Tools

Mobimex 94 offers a wide range of equipment

• The Format-4 control system has been specifically designed to perform cutting, milling and drilling operations. The operation interface is intuitive using a Windows graphics system, with buttons to simplify operation.

• Editor software: CAD functions (flipping the image, rotate, repeat, etc ...). A graphical view for 5 different sides, parametric programming with geometric and mathematical formulas assisted up to 300 variables.

A programming for a direct treatment, horizontally, vertically and also for all the directions possible and imaginable. Programming a single hole drill, multiple holes, or lines.

Programming straight lines, curves, oval ellipses, milling, profiling and cutouts.

• Automatic writing, and bold italic fonts, cut letters: 3 standard profiling letters (single, island or both combined).

Machine: Holz-Her Sprint 1310-1

• Working length: 3700 mm

• Working width: 1300 mm

• Max. with borders: 8 mm

• Max. working height: 50 mm

• Speed: 12 m / min

• Granulated thermo adhesive

• Applies for: veneer, ABS, Wood

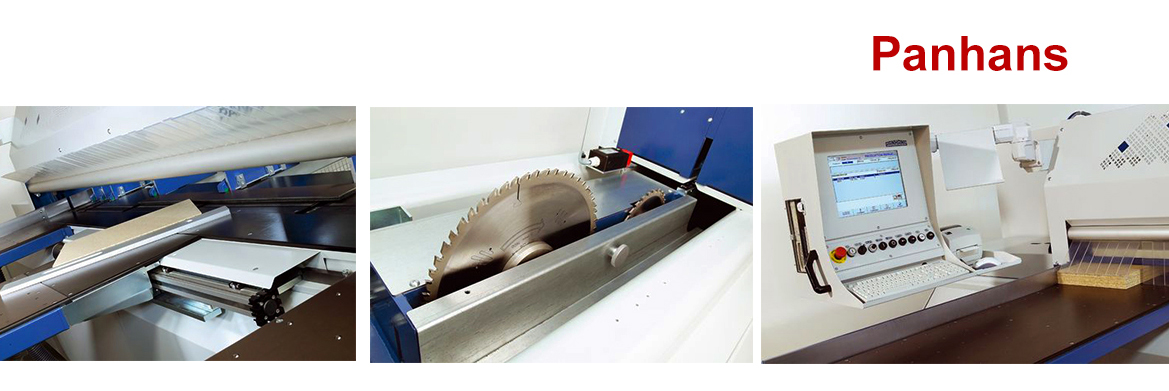

TECHNICAL SPECIFICITY

• Driving speed: 80 m / min

• Possibility of cutting by "packets", maximum size of cut: 72 mm

• Ultra-precise cut

• Operation: the cutting diagram is displayed on the screen, in parallel with the cutting cycle

PRO-CENTER is the most professional machine in the field. With PRO-CENTER, we carry out all the drilling and insertion necessary for the assembly of our products - both horizontally and vertically. A complete modular system (adjustment plans, drill heads and managers) ensures that the PRO-CENTER will manage an individual treatment. PRO-CENTER is recommended for:

• Hinges: Drilling / pressing

• Mounting plates: Drilling / pressing

• Front assembly: Drilling / pressing

• Series of holes: Drilling

• Rails corps: forage (horizontal)

• Wooden dowel holes

• Forage pour BLUMOTION Avantages

• Precision machining

• Vertical drilling and mounting hardware

• Horizontal drilling

• Drill heads changed without tools

• Quick change of leaders who have special predefined caps

• Adjustment of the settings is done according to the plan

• Adjusting drilling depth distances